In a significant collaboration, UVeye, an automotive technology company specializing in computer vision and artificial intelligence for drive-through inspection systems, partners with Hypertec, a global leader in manufacturing and assembling sustainable technology solutions. The strategic alliance aims to initiate mass production of UVeye’s products, addressing the escalating demand for their inspection systems across the country. The production will take place at Hypertec’s facilities located in Plainfield, Indiana, and Montréal, Canada.

This partnership enables UVeye to install systems within 45 days of signing, ensuring swift and efficient integration for industry players.

Driving Manufacturing Innovation

UVeye’s collaboration with Hypertec aims to enhance the production of their cutting-edge inspection systems, responding to the needs of their partners, including General Motors Co, Volvo Cars, CarMax, and the recent collaboration with Amazon, providing them hundreds of systems across the United States, Canada, Germany, and the United Kingdom. The production hub will be established at Hypertec’s advanced facilities in Plainfield, Indiana, and Montréal, Canada, underscoring the fusion of technology and sustainability. A team of engineering and technical experts from both UVeye and Hypertec will be formed to guarantee smooth and consistent installations, servicing, and training for manufactured systems.

This joint team of experts will oversee the assembly and manufacturing processes of UVeye’s three main products. Rigorous testing phases will be implemented to guarantee that each piece of equipment leaving the warehouse adheres to the high standards of quality and performance set by both UVeye and Hypertec.

UVeye’s Three Main Inspection Systems

Helios: An underbody scanner designed to detect a range of issues, from frame damage to missing parts, fluid leaks, and problems in the brake and exhaust systems.

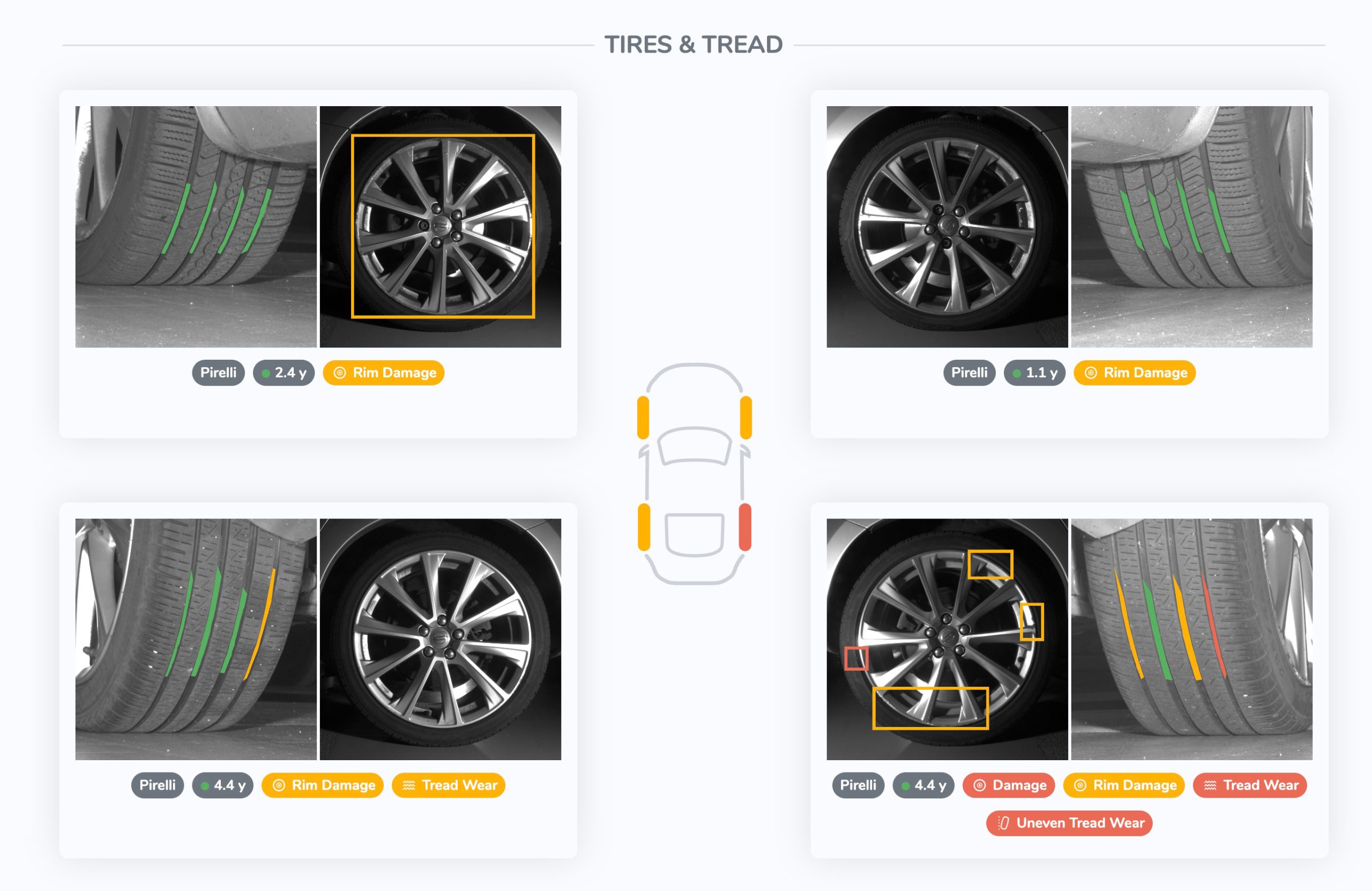

Artemis: A tire quality inspection system offering rapid identification of tire brand, technical specifications, air pressure, tread depth, sidewall damage, tire mismatches, and alignment issues within seconds.

Atlas and Atlas Lite: UVeye’s 360-degree vehicle-exterior detection system automatically identifies damages like scratches, dents, and imperfections. It meticulously examines sheet metal and external body components, providing comprehensive insights for manufacturers, fleets, and dealerships.

Exciting Future

Amir Hever, UVeye co-founder and CEO, expressed excitement about the partnership, emphasizing the exceptional performance of UVeye’s drive-through inspection systems.

“Our drive-through inspection systems have consistently demonstrated exceptional performance, detecting 96 percent of existing vehicle problems within seconds, in contrast to less than 25 percent accuracy for traditional manual checks. The demand for our technology has grown exponentially since its debut in North America at CES 2020 with hundreds of car dealerships, auction houses and fleets eagerly awaiting our increase in production. We are confident that partnering with Hypertec will propel us to the next level.”

Simon Ahdoot, President of Hardware Technology Solutions at Hypertec, emphasized the synergy between the two innovators, creating substantial value in the automotive solutions landscape.

“As a company committed to engineering excellence and operational prowess, we believe we are the ideal partner for UVeye. Our longstanding track record of large-scale manufacturing for innovative technology rollouts aligns perfectly with UVeye’s mission to deploy ground-breaking automotive solutions,” said Simon Ahdoot.